problems with heat staking|How Heat Staking with Induction Works : Tuguegarao Our non-contact induction staking solutions provide targeted, localized heating without open flame. Inserts are positioned within the coils of the induction heating system and .

Reopen the app after it closes to start using the Fun88 latest apk version. Update Fun88 App Fun88 Mobile site Overview. The Fun88 mobile version of the site offers a seamless betting and gambling experience on all operating systems and browsers. It automatically adjusts to the screen size of the device it is used from for optimal usability.

problems with heat staking,Problem: Cracking. Solution: Your temperature is too low, raise the temperature. When the post temperature isn’t high enough, cold deformation can cause the plastic to track. Having other issues with heat staking? We’re here to help. Contact Toman Thermosonics .The Miyachi EAPRO Desktop Systems are a line of (semi-) automatic systems developed for Heat-Staking. The Desktop Series deliver the same high bonding quality as the .Srcoll. Heat staking technology. Heat staking plastics. Whether PEEK, LCP, PPS or PPA: all thermoplastic materials can be processed with bdtronic's heat staking processes, even with a high glass fibre content. .Knurled Stake. Figure 7. Flush Stake. Branson Ultrasonics Corporation 41 Eagle Road, Danbury, CT 06813-1961 (203) 796-0400 • Fax: (203) 796-9838 .Heat Staking eliminates the need for extra hardware, which can become defective, break, or otherwise suffer from quality control issues. .

Our non-contact induction staking solutions provide targeted, localized heating without open flame. Inserts are positioned within the coils of the induction heating system and .

Our non-contact induction staking solutions provide targeted, localized heating without open flame. Inserts are positioned within the coils of the induction heating system and .

Post Views: 0. Step into the future of efficiency with a closer look at modern tech in manufacturing: heat staking machines. As the pace of technological . The Mayo Clinic and the United States' Centers for Disease Control and Prevention (CDC) define heat stroke as the result of the body overheating because of prolonged exposure to or physical .

Heat staking is a repeatable, economical and safe way to join two pieces of plastic or plastic and another material. One big advantage of heat staking is the ability to use the . The problems of the current inspection process of heat staking points in the automotive industry are that the process fully relies on the human labor and that human labor often incorporates inspection .

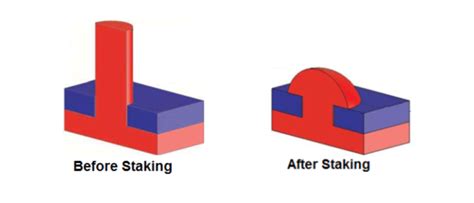

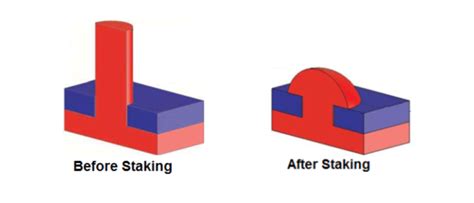

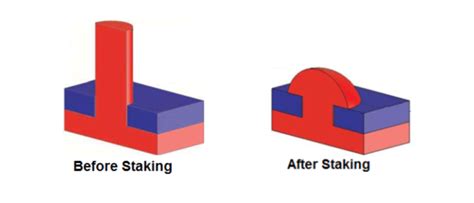

Heat Staking. Heat staking also known as thermoplastic staking is the process of joining two dissimilar materials together. In heat staking we use local heating and cooling to raise the temperature of plastic .

In the automobile manufacturing industry, inspecting the quality of heat staking points in a door trim involves significant labor, leading to human errors and increased costs. Artificial intelligence has .Heat staking technology is quite simple in concept. Whenever two or more components need to be attached to one another, and at least one is made of a thermoplastic, a combination of heat and pressure can be used to .

Heat-staking machines create hardware-free bonds that are less likely to break, wear down, or become problematic quality control issues. Not only will you be using the most modern methods for building your products, but you’ll also save on the cost of additional hardware and shorten the process for building altogether.Microsoft Word - heat_staking.doc. One of the most common uses. for induction heating is the heat. staking of threaded metal inserts. into plastic. Most thermo-plastics. are too soft to sufficiently hold a. thread, so brass or steel. threaded inserts are added.problems with heat staking Automated Machine Systems, Inc. (AMS) increases the productivity of manufacturers by helping them design, build and implement their factory automation systems. Learn about advanced technology for heat staking in the Automation 101 series from Automated Machine Systems, based in Cincinnati.Using Thermal Press for Heat Staking. Opposed to ultrasonic welding, heat staking and heat sealing offers more consistent and reliable joining of plastics, films, foils and filters within a product. The machines are automatable, offer greater flexibility with more components, and produce higher pull strength on the joints.Heat staking is a joining process of two pieces of plastic, or plastic and one other material, into a thermoplastic assembly via heat staking equipment. This process is an economical, repeatable and safe method for thermoplastic assemblies. . Toman’s heat staking equipment solves your production problems by combining multiple operations .problems with heat staking How Heat Staking with Induction Works Heat Staking Machines. Sonitek Heatstaking presses offer high speed, ergonomic & repeatable solutions for precise and repeatable thermal applications, like heat staking (riveting) of plastic bosses, insertion, filter & membrane sealing, and many more plastics joining applications.

Heat staking is a process which utilizes pulsed heat to join two or more parts together where at least one part is made out of plastic. It works by heating a plastic part to just above the glass transition temperature while simultaneously applying force so that it is deformed. The part is then cooled (still under force) to complete the process. Heat staking is a joining technology by which thermoplastic pins are formed by force and temperature to create a form- and force-fitting connection between components. This paper examines the characteristics of 3D printed pins in comparison to conventionally turned pins for heat staking applications. The 3D printed pins are .How Heat Staking with Induction Works The Heat Stake Advantage. Over the last 10 years, advancements in solid modeling technologies and subsequent changes in the injection molding industry have created the need for more complex and diverse assembly . Infrared plastic staking. InfraStake® is a tight, clean staking process that uses focused infrared energy to heat and form a plastic boss. This patented technology shines above other outdated, hot, .

TPI is better than the other heat staking source we have used: 1) Less operator requirements (plug & play); 2) Better fixture alignment and mounting” . Others on this list are difficult to work with. I like to work with companies like TPI since I have no problems with TPI. I am looking forward to working with TPI on future projects. Our .

Heat Staking. Heat Staking is a pulsed-heat process to join two or more parts out of which one at least is made of plastic. The process is to deform the plastic material using heat and force at a set process time. The bond is made by partially de-forming the plastic part in order to fix the other. Thermal cycle ranges, -50/75/spl deg/C, -55/100/spl deg/C, and -55/125/spl deg/C; corner staking on failure mechanisms for two thermal cycle profiles, -55/125/spl deg/C and -50/75/spl deg/C; and package interchangeability, i.e. using PBGA package on CGA pad design with a larger pad; heat sink attachment on the top of package. . The highly accurate result showed the good ability of the YOLO model to detect the heat staking points in the door trim image. Furthermore, the ResNet classification model also showed a noteworthy result; the accuracy of the model was 0.98, and the F1-score (the harmonic mean of the precision and recall) was 0.98.

Heat Staking. Heat staking also known as thermoplastic staking is the process of joining two dissimilar materials together. In heat staking we use local heating and cooling to raise the temperature of plastic components and allow plastic reforming to be carried out. This reforming can be used in a wide variety of applications.

problems with heat staking|How Heat Staking with Induction Works

PH0 · Why Use Heat Staking for Plastic Assembly Projects?

PH1 · Why Use Heat Staking for Plastic Assembly Projects?

PH2 · Thermal Staking Design Guidelines

PH3 · Staking plastic using heat and pressure

PH4 · Problems with Heat Staking

PH5 · Modern Tech: Heat Staking Machines and Why You Should Be

PH6 · How Heat Staking with Induction Works

PH7 · Heat stroke: Prevention, treatment vs body overheating

PH8 · Heat staking plastics

PH9 · HEAT STAKING FUNDAMENTALS

PH10 · Application of YOLO and ResNet in Heat Staking